CNC Machining

- Capabilities

- CNC Machining

Our equipment and machinery is modern and state of the art. Our 20,000 square foot factory is capable of extension to suit your needs.

Mazak 100MSY

- Read More

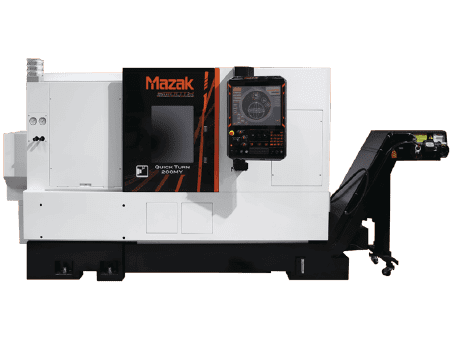

Mazak 200MY

- Read More

Mazak Integrex 100 IV S

- Read More

Mazak Integrex i200 S

- Read More

Mazak VCN 530C

- Read More

Mazak VTC-200

- Read More

Mazak FJV-250

- Read More

Mazak Variaxis 630-5X 2PC

- Read More

Mazak Variaxis i500 2PC

- Read More

Mazak VCN 410-B

- Read More

Mazak 6T

- Read More